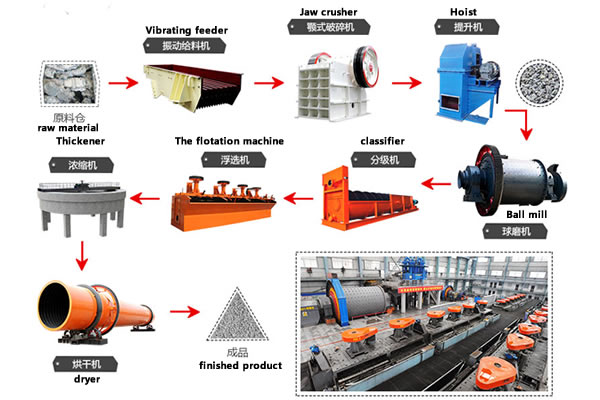

Gold mine ball mill beneficiation process site

Production capacity: 0.18-7m ³/ min

Processing materials: processing materials: copper, zinc, lead, nickel, gold and other non-ferrous metals

Equipment configuration: jaw crusher, elevator, ball mill, classifier, flotation machine, mixing bucket, high-efficiency concentrator and dryer

The ball mill flotation production line configured by our company is widely used in the roughing and cleaning of copper, zinc, lead, nickel, gold and other non-ferrous metals, ferrous metals and non metals. The whole production line has excellent linearity, and it is easy to control the grinding fineness, flotation mass fraction and pulp acidity and alkalinity.

The mined ore is initially crushed by a jaw crusher, and after being crushed to a reasonable fineness, it is uniformly sent to a ball mill through a hoist, and the ore is crushed and ground by a Ore dressing ball mill . The ore fines milled by the ball mill enter the classifier, which cleans and classifies the ore mixture based on the principle that the specific gravity of solid particles is different and the precipitation speed is different in the liquid. The washed and graded minerals are sent to the flotation machine, and different drugs are added according to different mineral characteristics to separate the required minerals from other substances. After the required minerals are separated, because they contain a large amount of water, they must be preliminarily concentrated by a thickener and then dried by a dryer to obtain dry minerals.