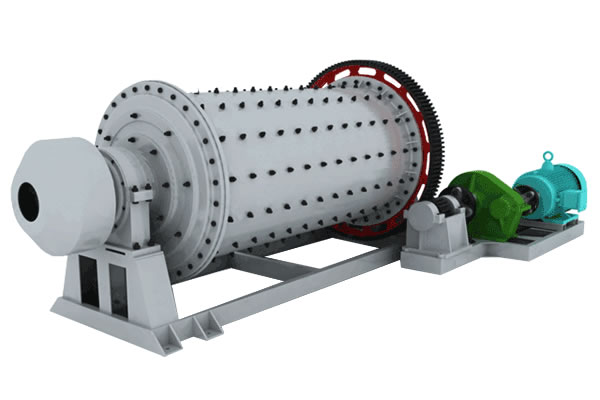

Process flow of steel slag ball mill

The process flow of steel slag ball mill typically includes the following steps:

Raw material preparation: The steel slag to be processed is classified and screened, removing impurities and large particles, to obtain uniformly fine particles.

Ball milling: The pre-treated steel slag material is added to the ball mill. Through the high-speed rotation and friction of the ball mill, the steel slag particles are continuously ground and polished to achieve the purpose of refining and improving quality.

Classification: The ball-milled steel slag material is classified by a sieve to obtain steel slag powder of different particle sizes.

Magnetic separation: The ball-milled steel slag powder is subjected to magnetic separation treatment to remove ferromagnetic impurities and metal iron and improve the quality of the steel slag.

Packaging: The processed steel slag powder is packaged according to specifications and requirements, stored, or sold.

The above is the general process flow of steel slag ball mill, and the specific process may vary slightly depending on the process requirements, equipment performance, and product quality requirements of different factories."

Company:Xinxiang Tongjia Industrial Equipment Technology Co., Ltd.

Phone:086+18568631888

Email:info@aballmill.com

WhatsApp:086+15138925611