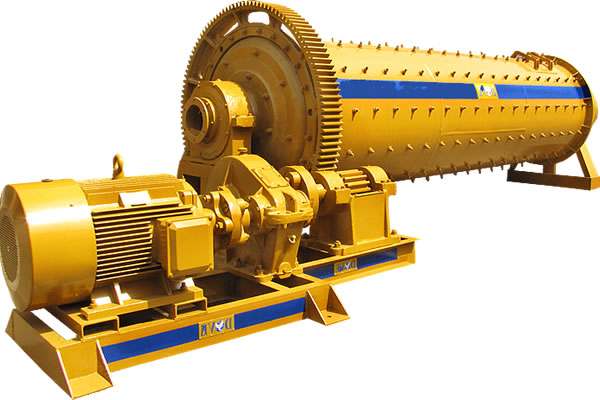

Rod mill

33 Items in Stock

Brief introduction The rod mill is a kind of equipment with professional crushing materials as fixed particles. It is basically the same as the internal structure and working principle of the ball mill, but the ball mill is used for the gri

Brief introduction

The rod mill is a kind of equipment with professional crushing materials as fixed particles. It is basically the same as the internal structure and working principle of the ball mill, but the ball mill is used for the grinding of steel balls and linings. The rod mill is steel ball, steel forging and Lining effect, in fact, it can be said that the rod mill is also the correct for the ultra-fine crusher.

working principle.

The rod mill enters the tank from the grinding head into the rod mill through the screw feeding device. After entering the tank, it enters the first stage of crushing granules. Material, steel ball, steel forging with rod grinding The clockwise rotation of the machine returns to the third quadrant of the circle of the rod mill and the second quadrant of the second quadrant to start the parabolic motion, and finally falls to the tail material rotating with the rod mill. The material is manganese steel under the material. Liner, so after multiple impacts, we will form the desired particle size material.

Use

Use

Because the rod mill is different from the over-grinding of the ball mill, the rod mill is widely used. As long as the material with hardness is broken into small particles (non-powder) which is evenly granulated through the production line, a rod mill can be used. It is said that quartz sand, quicklime, tungsten tin ore, rare metal ore re-election or magnetic separation plant will choose a rod mill.

Advantage characteristics.

Relative crusher rod mill crushing particle process is not returning material, and there will be no over-pulverization. This is the biggest bright spot of the rod mill. In terms of power, it is very clever to add parabolic gravity, so the rod mill is very Energy-saving and consumption-reducing, do not want the teacher crusher to crush through the high-speed rotating hammer, and then through the vibrating screen screening is not suitable in the second through the conveyor into the crusher, the rod mill does not return material and through the steel Ball and steel forging ratios are very uniform for materials of different particle sizes, and another advantage of the rod mill is that it is not afraid of softness, so most of the rod mills are used in mining.

Technical Parameters

working principle.

The rod mill enters the tank from the grinding head into the rod mill through the screw feeding device. After entering the tank, it enters the first stage of crushing granules. Material, steel ball, steel forging with rod grinding The clockwise rotation of the machine returns to the third quadrant of the circle of the rod mill and the second quadrant of the second quadrant to start the parabolic motion, and finally falls to the tail material rotating with the rod mill. The material is manganese steel under the material. Liner, so after multiple impacts, we will form the desired particle size material.

Because the rod mill is different from the over-grinding of the ball mill, the rod mill is widely used. As long as the material with hardness is broken into small particles (non-powder) which is evenly granulated through the production line, a rod mill can be used. It is said that quartz sand, quicklime, tungsten tin ore, rare metal ore re-election or magnetic separation plant will choose a rod mill.

Advantage characteristics.

Technical Parameters

| Model | Cylinder(mm) | Cylinder speed(r/min) | Feeding granularity(mm) | Discharge size(mm) | Throughput(t/h) | Power(kw) | Gross weight(t) | |

| diameter | length | |||||||

| TJDL0918 | 900 | 1800 | 36-38 | ≤25 | 0.833-0.147 | 0.62-3.2 | 18.5 | 5.9 |

| TJDL0924 | 900 | 2400 | 36 | ≤25 | 0.833-0.147 | 0.81-4.3 | 22 | 6.7 |

| TJDL1224 | 1200 | 2400 | 36 | ≤25 | 0.833-0.147 | 1.1-4.9 | 30 | 13.9 |

| TJDL1530 | 1500 | 3000 | 29.7 | ≤25 | 0.833-0.147 | 2.4-7.5 | 75 | 19.8 |

| TJDL1830 | 1830 | 3000 | 25.4 | ≤25 | 0.833-0.147 | 4.8-11.6 | 130 | 34.9 |

| TJDL2130 | 2100 | 3000 | 23.7 | ≤25 | 0.833-0.147 | 14-35 | 155 | 46.5 |

| TJDL2136 | 2100 | 3600 | 23.7 | ≤25 | 0.833-0.147 | 19-43 | 180 | 48.7 |

| TJDL2430 | 2400 | 3000 | 21 | ≤50 | 0.833-0.147 | 25-65 | 245 | 59.7 |

| TJDL2736 | 2700 | 3600 | 20.7 | ≤50 | 0.833-0.147 | 32-86 | 380 | 92.5 |

| TJDL2740 | 2700 | 4000 | 20.7 | ≤50 | 0.833-0.147 | 32-92 | 400 | 95 |

| TJDL3245 | 3200 | 4500 | 18 | ≤50 | 0.833-0.147 | 64-180 | 630 | 149 |