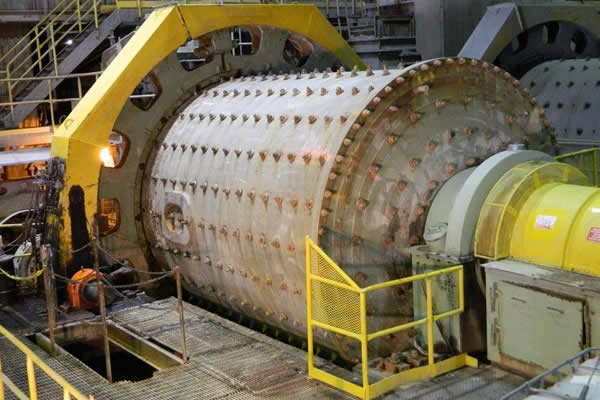

Steel slag ball mill

33 Items in Stock

Steel slag is a kind of smelting garbage. In the past, steel slag was buried as garbage. However, it is now a valuable material that many industries need after being crushed by a crusher and grinding into a ball mill. Since the amount of st

The meaning of steel slag ball mill

The steel slag ball mill belongs to one of the ball mill equipments. It is a new type of ball mill that is specialized and subdivided according to the characteristics of the steel slag. It is customized by the steel slag characteristics, the speed ratio, the weight of the ball mill, the quality of the ball mill liner and the steel ball. The design not only ensures that the steel slag ball mill grinds the steel slag quickly and efficiently, but also achieves the best energy saving state, so this is the significance of designing a new ball mill---steel slag ball mill.

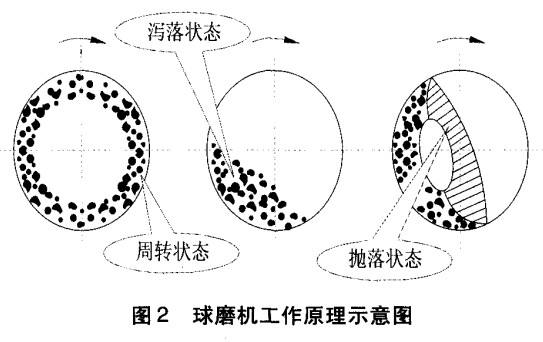

The grinding principle of steel slag ball mill

The steel slag ball mill is specialized in grinding steel slag, and its feed size does not exceed 25mm. Therefore, in general, the crusher is required to be coarsely broken in front of the steel slag ball mill, so that the discharge force of the crusher does not exceed 25mm, and the uniform steel slag particles enter the grinding head. In the cylinder of the steel slag ball mill, the steel slag and the steel ball inside the steel slag ball mill rotate with the uniform rotation of the steel slag ball mill until the height reaches the critical point of the third quadrant and the second quadrant, and the parabolic motion starts, so that the steel ball and the steel slag, the steel slag and The collision between the steel slag, the steel slag and the lining, and the steel slag, the steel ball and the lining plate can achieve the crushing and grinding effect, and the fineness requirement is discharged through the discharging head.

The price of the steel slag ball mill is more expensive than that of the ordinary ball mill. One is the professional ball mill, which has special advantages in technology and energy saving. The second is that the steel slag ball mill is relatively thick, because the hardness of the steel slag milled by the steel slag ball mill is about 7.5. Therefore, there are strict requirements and control on the weight of the ball mill itself and the quality of the steel plate. One is the new technology plus its own heavy weight, so the new steel slag ball mill is about 10-20% higher than the traditional ball mill, but the service life is twice as much as that of the ordinary ball mill. Overall, the new steel slag ball mill is cheaper.

Xinxiang City Tongjia Industrial have many years experience on design and installation of steel slag ball mill, has a very rich theoretical and practical experience, if you need to buy ball mill equipment, you can contact our Tongjia Industrial Ball Mill Office, we will be happy to help you! !

Wearing parts of Steel slag ball mill

The hardness of the steel slag polished by the steel slag ball mill is relatively hard. Therefore, the lining plate and the steel ball of the steel slag ball mill must be purchased as spare parts. Because the steel ball and the lining plate need to be cast according to the model, it is not the first to buy the spot. Under normal circumstances, the normal running time of the steel slag ball mill equipment production line is very valuable, so you should not buy it because the pre-stored wearing parts need to occupy the pressure, once the temperature appears, there will be a possibility of production stoppage.