Introduction to cement ball mill

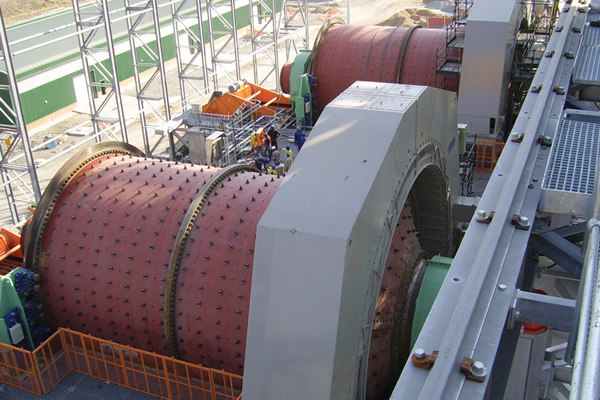

Cement ball mill is an indispensable grinding equipment in the cement production line. It has three different roles in the cement production line. One is grinding raw materials such as limestone, clay and iron slag. The second is clinker after grinding cement. , gypsum and mixed materials, etc., the third is the coal pulverizer used in the cement rotary kiln. The three ball mills are used in the cement production line. The first two are called cement ball mills, that is, The equipment we mainly introduce here, the coal mill, etc., will be shared separately for everyone.The principle of cement ball mill

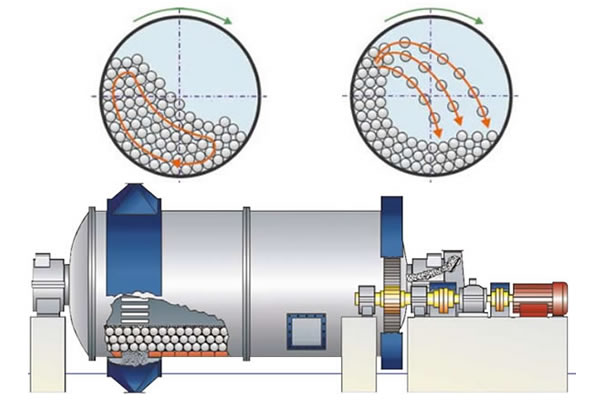

The principle of the cement ball mill is simply the conversion of energy. The electric energy is converted into kinetic energy by the electric motor, and the cement ball mill can be rotated. Then the cement ball mill carries the animal material and the steel ball. The steel ball is converted into potential energy by the power lifting height, and the potential energy is converted into downward. The gravity causes the steel ball, the raw material and the lining plate to collide and grind each other. Of course, the image is the cement ball of the cement ball mill and the material, the material and the lining plate, the collision grinding of the material and the material, the material is continuously refined, and the cement ball mill steel ball As the cylinder of the cement ball mill rotates at a constant speed, the steel ball is driven to the wall to reach a certain height. The parabolic motion is exhibited by the action of inertia and gravity. The work of the ball mill is continuous parabola, collision and grinding to achieve crushing and grinding.Cement ball mill

The cement ball mill is composed of a feeding screw device, a milled head, a milled tail, a hollow shaft, a supporting base, a discharging device, a transmission device and a cooling system.

Cement ball mill process

The cement ball mill is basically the same in the cement production line whether it is grinding raw material or grinding clinker. The feeding machine feeds the raw material into the cement ball mill through the spiral feeding end, and passes the steel ball and the material and the lining plate. After the impact and grinding, the specified particle size is reached through the raft to the second chamber and continue to grind until the wet cement ball mill or the air-sweep dry cement ball mill that meets the requirements is discharged from the ball mill discharge port. Grinding work, which is also a brief introduction to the ball mill process.

Cement ball mill parameters

Cement ball mill parameters

| Product specification (m) | Mill form | Transmission form | Reducer | Motor power (kw) | Throughput (t/h) | weight (t) | |

| Model | speed ratio | ||||||

| φ1.83×7 | Open flow | edge | ZD60 | 4.5 | 245 | 6.5-8 | 36 |

| φ2.2×7.5 | Loop current | edge | ZD70 | 5 | 380 | 8-10 | 56 |

| φ2.2×11 | Open flow | core | D110 | 35.5 | 630 | 12-13 | 104.6 |

| φ2.2×13 | Open flow | core | D110 | 35.5 | 630 | 16-18 | 114 |

| φ2.4×13 | Open flow | core | D110 | 35.5 | 800 | 20-23 | 171.5 |

| φ2.6×13 | Open flow | core | MFY100 | 19.5 | 1000 | 28-32 | 149.7 |

| φ3×9 | Loop current | edge | D125 | 41.2 | 1000 | 28-36.5 | 136.4 |

| φ3×11 | Loop current | core | D140 | 42.8 | 1250 | 36-47 | 180 |

| φ3.2×13 | Open flow | core | D140 | 36.5 | 1600 | 45-50 | 198 |

| φ3.8×13 | Open flow | core | MFY250 | 16.5 | 2500 | 60-62 |

204 |

Cement ball mill question and answer

1. Q: How to choose the model of cement ball mill? How to choose a manufacturer?

A: Hello! Tongjia Industry will answer your first question. The model selected for the cement ball mill needs to be configured according to your entire production line. What is the design output of your cement production line? For the cement ball mill model with the corresponding output, the second one is very simple for selecting the cement ball mill manufacturer. Which manufacturer's cement ball mill equipment is cheap and you choose which one, of course, Tongjia Industry is here to talk about the cheap price. Not everyone who chooses the lowest price, if you don't know well, you can communicate with us, we will give you a satisfactory answer! ! 0373-5881255/18903805495.

2. Q: How much is the cost of cement ball mill with capacity 8t/h?

Answer: The cement ball mill that produces Shidun can use 1830*7000 cement ball mill equipment with a weight of about 40 tons, so the price is about 380,000.

3. How long does it take to replace the steel ball and liner of the cement ball mill?

Answer: The cement ball mill steel ball and the lining plate are all wear parts. The specific replacement time needs to be based on the material particles and the work market and site investigation. Of course, the lining steel ball casting takes time, so there will usually be a set of spare lining and Steel ball.