Ball mill

33 Items in Stock

Brief Introduction of Ball Mill Ball mill is an important equipment for secondary crushing. After one crushing, the qualified size of raw material particle group is formed after the vibration screen is deleted. The raw material particle ent

Brief Introduction of Ball Mill

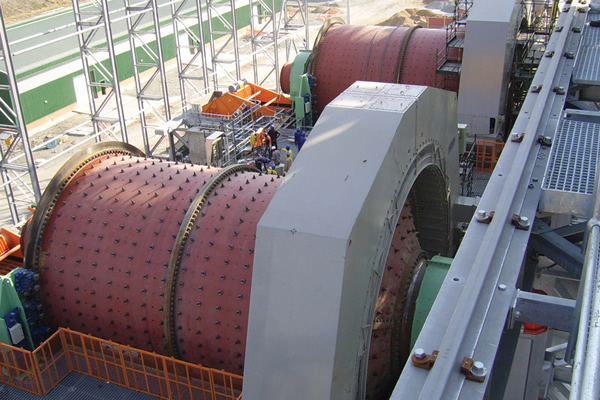

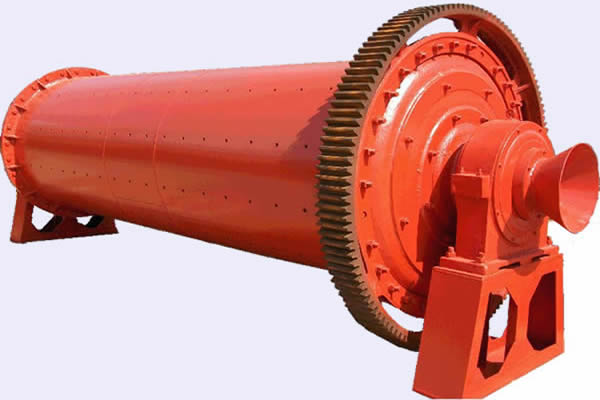

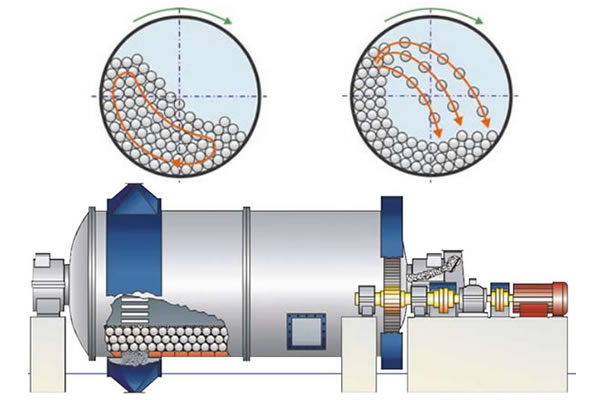

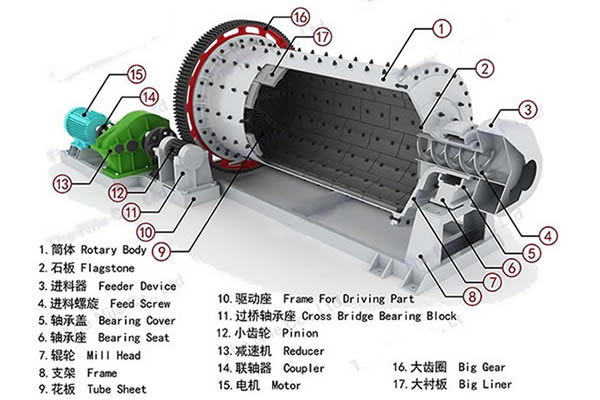

Ball mill is an important equipment for secondary crushing. After one crushing, the qualified size of raw material particle group is formed after the vibration screen is deleted. The raw material particle enters the silo from the screw hollow shaft of the mill, and then impacts on the material through the steel ball in the cabin to smash the material. After several impacts, the material is grinded by the ball mill. Art process. Ball mill is widely used. According to the industry characteristics, it is gradually refined into tubular ball mill, bar ball mill, cement ball mill, ultra-fine layer press mill, hand ball mill, horizontal ball mill, ball mill bearing, energy-saving ball mill, overflow ball mill, ceramic ball mill, grid ball mill.Principle of Ball Mill

Structure of ball mill

Advantages of Ball Mill

1. Ball mill is widely used for secondary grinding of calcium carbonate (calcite), sericite, illite, copper ore, gold ore, dickite, pyrophyllite, wollastonite, barite, kaolinite (coal-bearing kaolin), graphite, colloidal sand and other metal and non-metallic ore fine grinding process.

2. The grinding effect of the ball mill is very good and the operation is relatively stable. The new energy-saving and environmental protection ball mill is more efficient, energy-saving, low noise operation and maintenance.

3. The feed size of the ball mill is not more than 25 mm, the crushing and discharging materials are uniform, and the fineness is between 0.074-0.4 mm. The fineness is set according to the requirements.

4. Ball mill runs steadily, lining plate and steel ball can be replaced regularly, and the main body of ball mill will not be harmed.

5. The output of ball mill is high, and the maximum output can reach 600 tons per hour.

Ball mill parameters

| Model |

speed (r/min) |

Ball loading weight (t) |

Feed particle size (mm) |

Discharge particle size (mm) |

yield (t/h) |

Motor power (kw) |

Equipment weight (t) |

| Ф900×1800 | 36-38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 |

| Ф900×3000 | 36 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 |

| Ф1200×2400 | 36 | 3 | ≤25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 |

| Ф1200×3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 |

| Ф1200×4500 | 32.4 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 |

| Ф1500×3000 | 29.7 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 19.5 |

| Ф1500×4500 | 27 | 11 | ≤25 | 0.074-0.4 | 3-6 | 110 | 22 |

| Ф1500×5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 |

| Ф1830×3000 | 25.4 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 34.5 |

| Ф1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 | 38 |

| Ф1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 | 43 |

| Ф1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 |

| Ф2100×3000 | 23.7 | 15 | ≤25 | 0.074-0.4 | 6.5-36 | 155 | 45 |

| Ф2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 | 56 |

| Ф2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 12-48 | 280 | 59.5 |

| Ф2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 | 54.5 |

| Ф2200×6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 | 61 |

| Ф2200×7000 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 62.5 |

| Ф2200×7500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 64.8 |

| Ф2400×3000 | 21 | 23 | ≤25 | 0.074-0.4 | 7-50 | 245 | 58 |

| Ф2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 8.5-60 | 320 | 72 |

| Ф2700×4000 | 20.7 | 40 | ≤25 | 0.074-0.4 | 22-80 | 380 | 95 |

| Ф2700×4500 | 20.7 | 48 | ≤25 | 0.074-0.4 | 26-90 | 480 | 102 |

| Ф3200×4500 | 18 | 65 | ≤25 | 0.074-0.4 | 按工艺条件定 | 630 | 149 |

| Ф3600×4500 | 17 | 90 | ≤25 | 0.074-0.4 | 按工艺条件定 | 850 | 169 |

| Ф3600×6000 | 17 | 110 | ≤25 | 0.074-0.4 | 按工艺条件定 | 1250 | 198 |

| Ф3600×8500 | 18 | 131 | ≤25 | 0.074-0.4 | 45.8-256 | 1800 | 260 |

| Ф4000×5000 | 16.9 | 121 | ≤25 | 0.074-0.4 | 45-208 | 1500 | 230 |

| Ф4000×6000 | 16.9 | 146 | ≤25 | 0.074-0.4 | 65-248 | 1600 | 242 |

| Ф4000×6700 | 16.9 | 149 | ≤25 | 0.074-0.4 | 75-252 | 1800 | 249 |

| Ф4500×6400 | 15.6 | 172 | ≤25 | 0.074-0.4 | 84-306 | 2000 | 280 |

| Ф5030×6400 | 14.4 | 216 | ≤25 | 0.074-0.4 | 98-386 | 2500 | 320 |

| Ф5030×8300 | 14.4 | 266 | ≤25 | 0.074-0.4 | 118-500 | 3300 | 403 |

| Ф5500×8500 | 13.8 | 338 | ≤25 | 0.074-0.4 | 148-615 | 4500 | 525 |