what is lime ball mill?

A lime ball mill refers to a type of ball mill specifically designed for the grinding of lime or similar materials. It is a key piece of equipment in the process of making quicklime by the calcination of limestone (calcium carbonate). The lime ball mill plays a crucial role in various industries, particularly in the production of lime for applications such as construction, agriculture, water treatment, and more.

Here are key features and aspects of a lime ball mill:

1. Raw Material: The primary raw material processed in a lime ball mill is limestone (CaCO₃). The limestone is typically quarried and then finely ground to form a powder, known as quicklime or calcium oxide (CaO).

2. Grinding Process: In the lime ball mill, the finely ground limestone is mixed with water to form a slurry. The slurry is then fed into the ball mill where it undergoes grinding and further size reduction. The grinding action is achieved by the rotation of the mill and the impact of grinding media (usually steel balls) on the slurry.

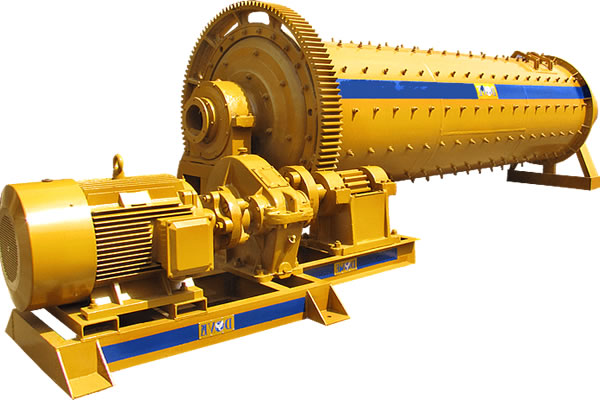

3. Ball Mill Structure: The lime ball mill has a drum or cylinder that rotates on its axis. The length and diameter of the drum can vary based on the capacity of the mill and the desired fineness of the product.

4. Grinding Media: Steel balls are typically used as grinding media in a lime ball mill. The size and type of the grinding media can influence the grinding efficiency and the final particle size distribution.

5. Slurry Preparation: The limestone slurry is prepared by mixing water with the finely ground limestone. The slurry is then introduced into the ball mill for further processing.

6. Calcination Process: The lime ball mill is part of a larger process that involves the calcination of limestone. The finely ground limestone undergoes high-temperature calcination to produce quicklime (CaO) and carbon dioxide (CO₂).

7. Controlled Environment: The lime ball mill operates in a controlled environment where factors such as rotation speed, grinding media size, and slurry concentration are carefully regulated to achieve the desired product quality.

8. Product Handling: After the grinding process in the lime ball mill, the resulting slurry may undergo further processing steps or be directed to other equipment for further treatment, depending on the specific application.

Lime ball mills are essential in the production of lime, which has a wide range of applications, including soil stabilization, water treatment, steel manufacturing, sugar refining, and various construction activities. The efficiency and control of the lime ball mill are critical for producing high-quality lime products.

Company:Xinxiang Tongjia Industrial Equipment Technology Co., Ltd.

Phone:086+18568631888

Email:info@aballmill.com

WhatsApp:086+15138925611