What can we do when the water temperature of the cement ball mill is too high

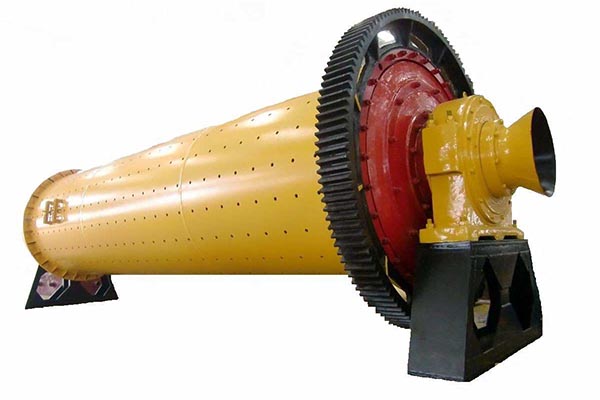

Cement ball mill is an indispensable equipment in the cement plant, so the frequency of use of the cement ball mill is very high, which will inevitably encounter some situations where the temperature of the ball mill is too hot.

We have to find the cause from various aspects to solve this problem. First, we must reduce the temperature of the clinker:

1. Strengthen the management of materials, to avoid clinker with high temperature entering the grinding head bin, and prohibit red material from entering the grinding;

2. Spray water on the clinker belt during grinding;

3. Spray water in the cooler to reduce the temperature of the clinker.

The temperature of the cement ball mill is too high to strengthen the heat dissipation of the grinding system:

The grinding system has a large number of equipment and pipes, and the heat dissipation surface is large. To strengthen the heat dissipation of the system, it is mainly to use the surface of the system to strengthen the cooling and dissipate heat, such as spraying atomized water to the outer wall of the powder separator, and making a water tank along the outside of the screw conveyor. The test proves that the temperature of the cement is reduced but not obvious, and it is easy to cause water in the equipment, so it should be used with caution.

Company:Xinxiang Tongjia Industrial Equipment Technology Co., Ltd.

Phone:086+18568631888

Email:info@aballmill.com

WhatsApp:086+15138925611