How to improve the service life of ball mill bearings?

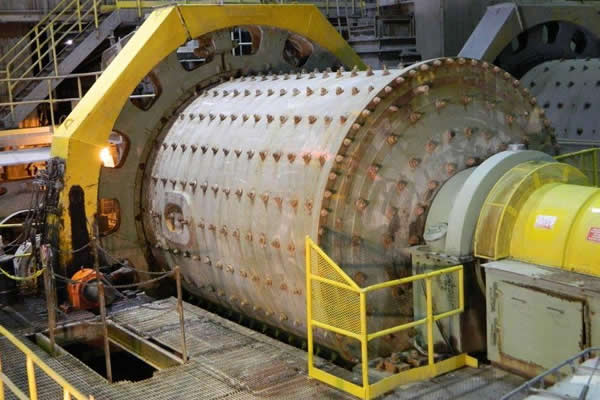

How to improve the service life of ball mill bearings? Ball mill bearings are important equipment for ball mills. Xinxiang Tongjia industrial equipment technical engineer research found that the outstanding problem of ball mill is the service life of ball mill bearings. An automatic line grinding method composed of a high-performance and high-stability machine tool system is suitable for super-machined, low-noise ball bearings, which can avoid collisions, reduce transmission errors, eliminate human factors, improve processing efficiency and quality consistency, and reduce production. Cost and improve business efficiency. How to improve the service life of ball mill bearings? Listen to the technical staff of the technical department of the ball mill manufacturer.

Do daily maintenance work to improve the service life of ball mill bearings.

The ball mill should pay attention to and lubricate the friction surface in time to ensure the normal operation of the ball mill and prolong the service life of the equipment. The grease added into the bearing seat is 50% -70% of the volume. It must be replaced every three months. When changing the oil, carefully clean the bearing roller slide with clean gasoline or kerosene. When the bent plate is in contact with the bent plate pad, grease must be injected before the ball mill is started. Bearing parts are easily damaged. Due to the greater wear during use, frequent maintenance and refueling are required to increase the service life of the bearing.

Each friction surface of the ball mill generally has two types of lubrication: dry oil lubrication and thin oil lubrication. Large and medium-sized ball mills use large oil circulation lubrication for large and small transmission gears, transmission bearings, reducers and ground bearings, and some large and small transmission gears and transmission shaft bearings are also lubricated with dry oil. Practice has proved that large and small transmission gears and sliding bearings are lubricated with thin oil, and rolling bearings are lubricated with dry oil. Thin oil lubrication is better than pressure circulation oil lubrication, which is conducive to the stable operation of the ball mill and prolongs the service life of the parts. The transmission gears of small rolling mills are mostly lubricated with dry oil, but the effect of thin oil lubrication is better.

Through the above introduction, I believe you have a detailed understanding of "how to improve the service life of ball mill bearings", and I hope to help you. In normal daily use, it is necessary to do daily maintenance of the ball mill to improve the service life of the ball mill bearing. If you have any questions about the ball mill, you are welcome to consult our online experts and we will be happy to assist you.