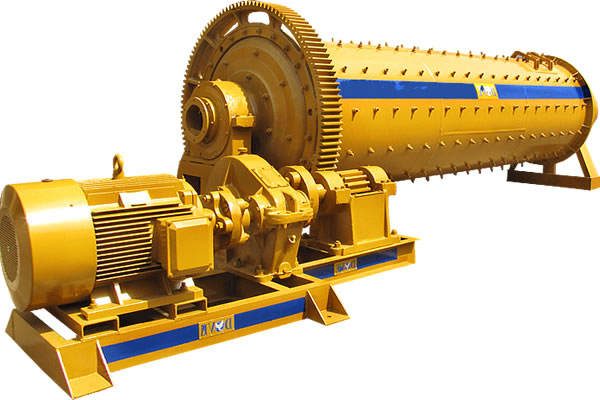

How to improve ball mill output quality and reduce power consumption

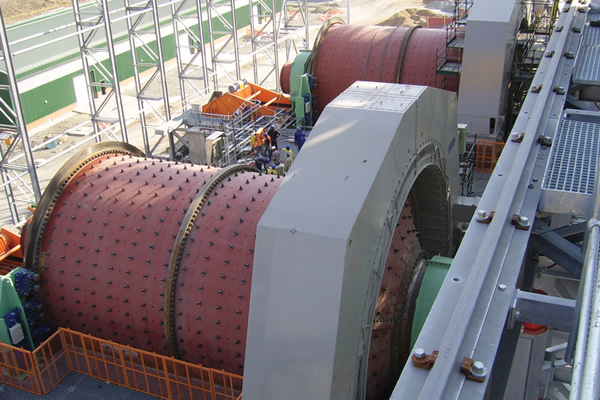

The power consumption of raw meal and cement ball mills accounts for about 23% of the power consumption of cement plants and about 13% of the cost of cement. Therefore, in order to reduce power consumption, reduce costs, and improve economic efficiency, it is necessary to significantly increase the mill output. After the grinding output is greatly increased, the power consumption per unit of production will be reduced, the power consumption of the cement plant will be greatly reduced, the economic benefits will be significantly improved, and the social power shortage will also be reduced.

Second, reduce the water content of the abrasive material. At present, the air-sweep type & 40 is used, that is, the hot air in the hot blast furnace or the waste gas from the rotary kiln is blown into the raw material mill, and the dry type & 41; Nanjing Yuke Building Material Technology Co., Ltd. air-swept raw material pulverizer doubled its output after being applied in a certain enterprise; or the existing rotary dryer was transformed to improve its heat exchange area and thermal efficiency.

Third, strengthen the mill ventilation. While strengthening the ventilation, it is necessary to reduce the ventilation resistance and increase the number of grids and ventilation area while ensuring the strength of the partition. In addition, lock the air at the material outlet to prevent air leakage.

Fourth, the classification and loading capacity of abrasive materials. Whether the grading and bearing capacity of the abrasive is appropriate needs to be tested through production practices. After the new ball-matching plan is put into production, if the fineness meets the requirements and the output is high, it means that the ball-matching plan is suitable, otherwise it needs to be improved or rematched; after a certain period of time, it is necessary to perform ball-refilling and ball-clearing.

Fifth, strengthen grinding machine technical training. In the case of no automatic control, the mill operator should be able to hear the grinding sound, adjust the feed amount according to the grinding sound, make the feed amount match the grinding capacity, control the fineness, and strengthen the maintenance of the equipment Maintenance to ensure the normal and safe operation of the mill.

Company:Xinxiang Tongjia Industrial Equipment Technology Co., Ltd.

Phone:086+18568631888

Email:info@aballmill.com

WhatsApp:086+15138925611