Installation precautions for ball mill parts

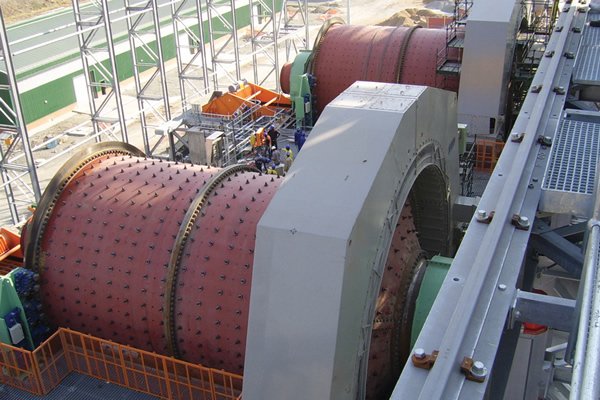

Installation is the first task of the ball mill, and it is also the most important process, because the installation of the ball mill is directly related to the future use, such as crushing rate, production volume, failure rate and so on. Therefore, the technical personnel summarized the points that need to be paid attention to during the installation. The following are the precautions for the installation of the ball mill parts.

2.Cylinder: Before installation, pay attention to thoroughly clean the mating surface of the cylinder flange and the end cover, remove oil and burrs, remove the rust-proof oil in the flange surface, hollow journal and connection hole, and ensure that the flanges are dry and clean , But care should be taken to protect the assembly mark.

3.Ball mill tank: When installing the ball mill tank, the two ball mill tanks should be of equal mass to ensure the balanced operation of the ball mill. Most ball mill tanks cannot be installed.

4.Main base plate: Before installing the main base plate, care should be taken to clean the rust-proof oil and rust on each working surface to remove burrs. If there is any paint in contact with the base plate, it must be cleaned until it completely sees the metal.

5.Base: When the base is installed, it must be re-irrigated to enhance stability and prevent it from stepping down.

6.Feeding port: It should be noted that after the feeding part is installed in the rotating part, all the screws that are firmly installed on the feeding port should be tightened to the maximum extent. The feeder and spoon should not be loosened.

7. Pinion: When installing, pay attention to the temporary support between the lower connecting flange of the gear cover and the foundation, which can prevent the gear cover from interfering with the gear shaft. And the pinions on both sides must be installed the same.