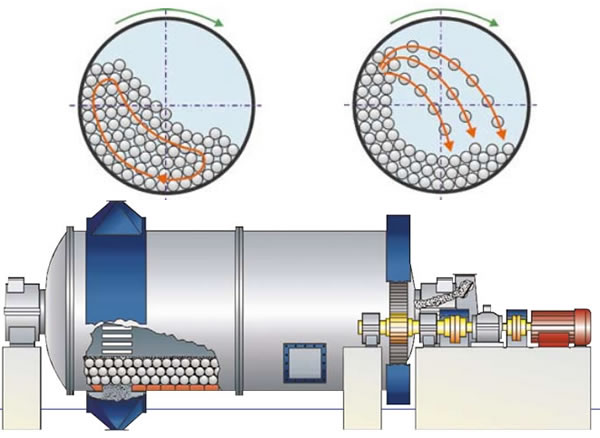

The working principle of the ball mill

The ball mill can dry or wet all kinds of ore and other grindable materials. It is the key equipment for crushing the material after it is crushed. This article mainly introduces the working principle of the ball mill.

The ball mill is mainly composed of a cylindrical barrel, an end cover, a bearing and a transmission ring gear. The barrel with a fixed large gear ring can roll, and a steel ball with a diameter of 25-150 mm is installed in the barrel. There are end covers at both ends of the cylinder. The end covers are connected to the end flange of the cylinder by screws. The middle of the end cover has a hollow journal. The hollow journal is supported on the bearing.

In the drive system, the electric idea drives the large gear ring and the cylinder to slowly roll through the coupling, reducer and small gear. When the cylinder rolls, the steel ball rises to a certain height with the cylinder wall and then drops in a parabola. Because the end cap has a hollow journal, the material is fed into the cylinder from the left hollow journal and gradually diffuses to the right. During the movement of the material from left to right, the rotating cylinder will bring the steel ball to a certain height. When its own gravity is greater than the centrifugal force, it will drop from the inner wall of the cylinder and fall, relying on the impact to crush the ore.

In addition, the steel ball also has a grinding effect on the material, and the entire moving process is also a process of crushing and destroying the material. A grid plate is installed at the right end of the grid ball mill. The crushed material enters between the grid plate and the end cover, and then the material is raised by the lifting plate. The material slides along the lifting plate to the right through the conical block to the hollow journal. The hollow journal is then discharged outside the machine.