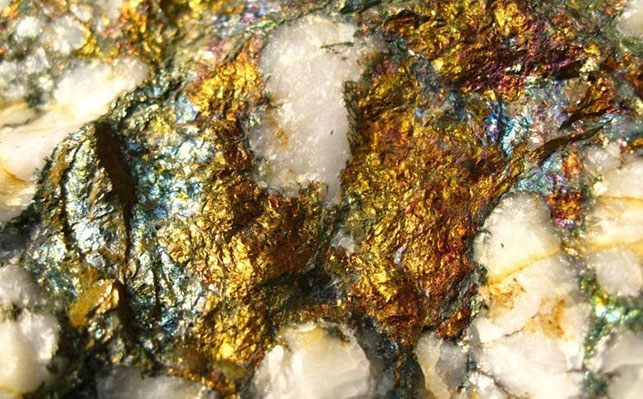

Gold ore crushing and grinding process

Before the ore enters the sorting process, the material needs to be crushed and ground to fully dissociate the ore, and the ore is first sent to the crusher for crushing to a certain particle size. This process needs to go through one or two or more stages of crushing. In the process, the particle size is distinguished by the screening machine in the middle, and the qualified gold minerals are directly sent to the ball mill to continue grinding.

The materials entering the grinding stage are similar to crushing. They need to go through one or two or more stages of grinding operations. This link needs to be classified by cyclone or classifier equipment. The qualified grinding materials directly enter the sorting stage, not the qualified materials. It needs to be classified and returned to the gold ball mill to continue grinding.

Why should the grinding operation be carried out before gold beneficiation?

1>It is to coarsely crush and grind bulk materials;

2>It is to ensure the stability of beneficiation index, high concentrate grade and tail grade, and at the same time, it is necessary to separate minerals and gangue minerals.

In the process of gold ore beneficiation equipment, the indicators are unstable, the concentrates are side-by-side, the tailings are high, and the medium mineral rate is high. The reason is often due to insufficient dissociation. Therefore, crushing and grinding are indispensable and important links before sorting.

Crushing and grinding can provide selected materials with high degree of dissociation of useful minerals for sorting operations. Judging from the structure of the minerals, there are very few ores inlaid with coarse-grained dissociated particles directly obtained after crushing, and most of the ores must be ground to obtain a relatively high degree of dissociation. Therefore, crushing is to prepare raw materials for grinding, and grinding is the continuation of crushing. Ball mill equipment grinding is the final process to achieve full dissociation.

According to the survey, most of the gold processing plants in my country use jaw crushers for coarse crushing, standard cone crushers for medium crushing, and short-head type cone crushers for fine crushing. Medium and small gold dressing plants mostly use two stages and one closed circuit crushing process, while large gold dressing plants mostly use three stages and one closed circuit crushing process.

Company:Xinxiang Tongjia Industrial Equipment Technology Co., Ltd.

Phone:086+18568631888

Email:info@aballmill.com

WhatsApp:086+15138925611